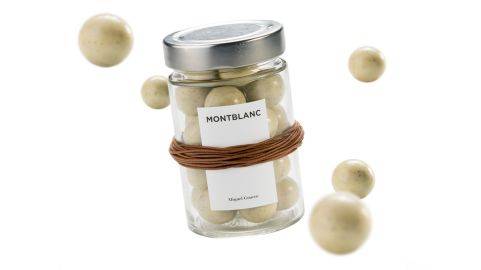

Dragées Montblanc

Inspirations :

J'ai créé ce dessert pour permettre au consommateur de transporter peu importe l'endroit cette pâtisserie classique qui est le Mont-Blanc et d'expérimenter le plaisir de pouvoir manger un étonnant dessert dans n'importe quel endroit du monde.

Recipe

Kernel

First couverture chocolate

Second couverture chocolate

| ingredients | preparation |

|---|---|

|

Melt the couverture chocolate and mix with the remaining ingredients. |

Third couverture chocolate

| ingredients | preparation |

|---|---|

|

Melt the chocolate. Scrape the vanilla beans and integrate them into the chocolate with the hollow pods. Cover with plastic wrap and allow to infuse for 24 hours at 40°C.

|

Making the dragées

Pour a small quantity of the white chocolate into the turbine and then let it crystallize. Set the cold air to 10°C and the rotation speed to 60%, and gradually incorporate the couverture chocolate until there is no more white chocolate, while taking care to separate the kernels that have stuck together. Then gradually add the second couverture chocolate. Heat up and then repeatedly cool the dragées until you obtain a perfectly rounded shape. Let the dragées crystallize in the turbine as it rotates. Finish by incorporating the last couverture chocolate. Remove the dragées and clean the turbine. Return the dragees to the clean turbine, then set the hot air to 60°C and the rotating speed to 40%. As soon as the dragées have softened and are starting to stick together, set the cold air to 15°C and adjust the rotation so that they are constantly moving. Wait until the dragées acquire a glossy finish. As soon as the dragées shine, finish the crystallization process by setting the rotation to a slow speed, between 10 and 20%. Once they are well crystallized, remove the dragées from the turbine and package them. |