Celebrating 15 years of chocolate happiness in Suzhou, China

Celebrating 15 years of chocolate happiness in Suzhou, China

What could happen in 15 years? To different people, it could mean different things.

Just as a child grows from an infant to a teenager with great ambition in 15 years, Barry Callebaut’s chocolate factory in Suzhou, China, is similarly roaring and ready to take on new challenges.

Newman Chang, Site Manager for the Suzhou chocolate factory, says, “I joined the company in 2009, a year after we started our operations in Suzhou. Today, on January 9, 2023, we celebrate our 15th anniversary and I feel like a proud father. It’s like witnessing your child grow up. When we first started, we were still figuring out many things. But we learned along the way, and now we can do so much more.”

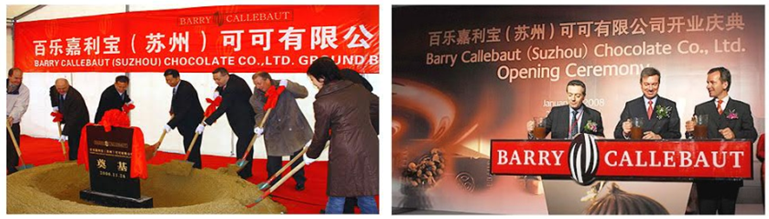

The birth of a chocolate manufacturing powerhouse

Before 2008, there was only one chocolate factory operational for Barry Callebaut in Asia Pacific in Singapore. After 12 months of construction, the Suzhou factory started production with around 10,000 tons of chocolate, through a handful of production lines for liquid and solid chocolate.

And 15 years whizzed by as the factory grew. To meet the rapid rise of local chocolate demand, the Suzhou factory increased both its capacity and capability.

Today, its chocolate production supports the needs of customers in multiple cities in Barry Callebaut’s Greater China portfolio, including Beijing, Hong Kong, Shanghai, Shenzhen, and Taipei, where the company has a direct presence in.

The future of chocolate-making in China

Creating manufacturing excellence

When the factory was first built, Newman was given one mission: to fill the factory with the buzzing activity of making chocolates.

Orders started pouring in, but quickly Newman and his team realized that they needed more. In particular, they needed more machines to produce what the customers wanted.

So, the Suzhou team got down to work and added more production lines to increase its capacity. The factory could now create multiple recipes of chocolate and meet higher volumes of demand. Still, it was not enough. They needed to increase the factory’s capability of making different formats of chocolate.

In the chocolate manufacturing world, producing white chocolate and chocolate that has flavoring and coloring requires dedicated production lines. In 2015, a white chocolate line was added. Then in 2019, a color and flavor line was added to the factory’s arsenal of production capabilities.

Today, Suzhou is one of Barry Callebaut’s largest factories in Asia Pacific, heading towards running at full capacity and catering to the full range of demands from chocolate consumers.

Pushing the needle in sustainability

Walking inside the Suzhou factory, it is clean, efficient, and brightly-lit. Quite unlike the scenes of Charlie and the Chocolate Factory movies.

But beyond what the eyes can see, there is another area of innovation – green energy. As the factory grew in stature, it also invested in the use of renewable energy to power its machines.

Currently, the team’s target for the next four years is to increase 4% of renewable energy as a part of the total energy usage every year. This carbon reduction roadmap contributes to Barry Callebaut’s Forever Chocolate ambition of becoming carbon-positive by 2025.

Women are a part of success

Traditionally, industrial chocolate factories like Barry Callebaut are filled with male factory workers. The reason is a practical one: most raw materials and finished goods are packaged in large, heavy quantities that require machinery and manual labor to move around.

But as the factory challenged itself to go beyond the status quo in its production, the local team also challenged the norm for diversity on the shop floor.

Production activities were segmented into more specific tasks, allowing females to work on tasks that suited their physical strength better. Roles were redrafted and soon the proportion of women working in the factory increased by 20%.

So, what’s next for the Suzhou factory?

It goes beyond producing for the popular “zang zang” chocolate dirty bun, or a refreshing chocolate ice cream.

Newman put it aptly: “Over the past 15 years, I’ve witnessed so many things. Foundations were built and skills were refined. I hope that after another 15 years, the Suzhou factory will have matured into a great man, leading the market in China and also for the region.”

Editor’s note: Many of our colleagues around the world have visited our Suzhou factory and played a role in growing this esteemed chocolate factory. We wish to thank you for your contributions. Join us today, in congratulating our colleagues in Suzhou and across China on their 15th Anniversary.