Raw materials

in Carma chocolate

Carma, Swiss beet sugar

SWISS SUGAR

Sugar is often an underestimated ingredient in the taste of chocolate. Swiss beet sugar is produced from locally grown and sourced sugar beets, contributing to our signature taste profiles. Our sugar farmers are required to meet standards of the Farm Sustainability Assessment (FSA), which helps them sell more sustainably produced agricultural products. The FSA also helps farmers assess, report and continuously improve their sustainability practices. We’re proud to work with suppliers who pass the FSA assessment.

Carma Swiss Chocolate

SWISS MILK

At Carma, we believe milk is not just milk. Because we are proudly Swiss and milk is part of our landscape and culture, we use only the best quality, locally sourced.

Switzerland has one of the world’s strictest animal welfare regulations and incentive programmes that ensure the wellbeing of milk cows throughout their lives. Healthy and happy cows, eating fresh grass and breathing clean Alpine air, produce high-quality milk and this is the ingredient that gives our couvertures their creaminess.

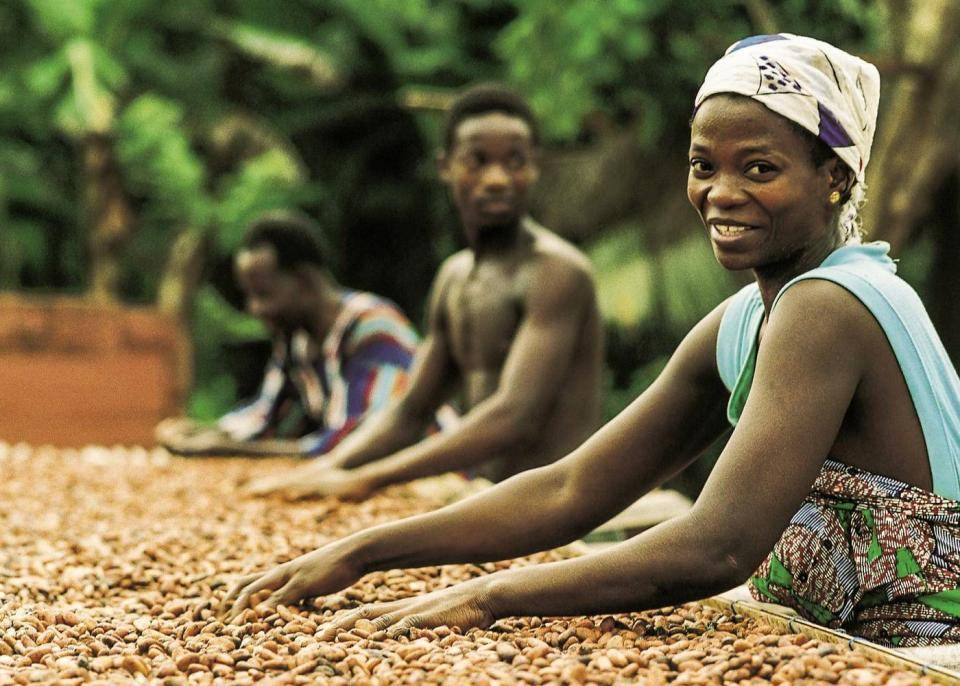

COCOA

Chocolate is not only about cocoa, but wouldn’t exist without it. Cocoa grows on the trees in tropical regions along the equator, where hot and humid climate promotes their growth. 70% of the world's supply comes from countries in West Africa: Côte d'Ivoire, Ghana, Nigeria and Cameroon. Nearly all our couvertures are blended with carefully selected UTZ-certified fine flavour cocoa beans.