From cocoa to chocolate

From cocoa to chocolate

Ever wondered how chocolate is made?

At the beginning, there are the cocoa beans, grown and harvested in the equatorial forests. Transforming the cocoa beans into chocolate is a complex process and requires several steps. In this short video, we show you how chocolate is made.

Where is cocoa grown?

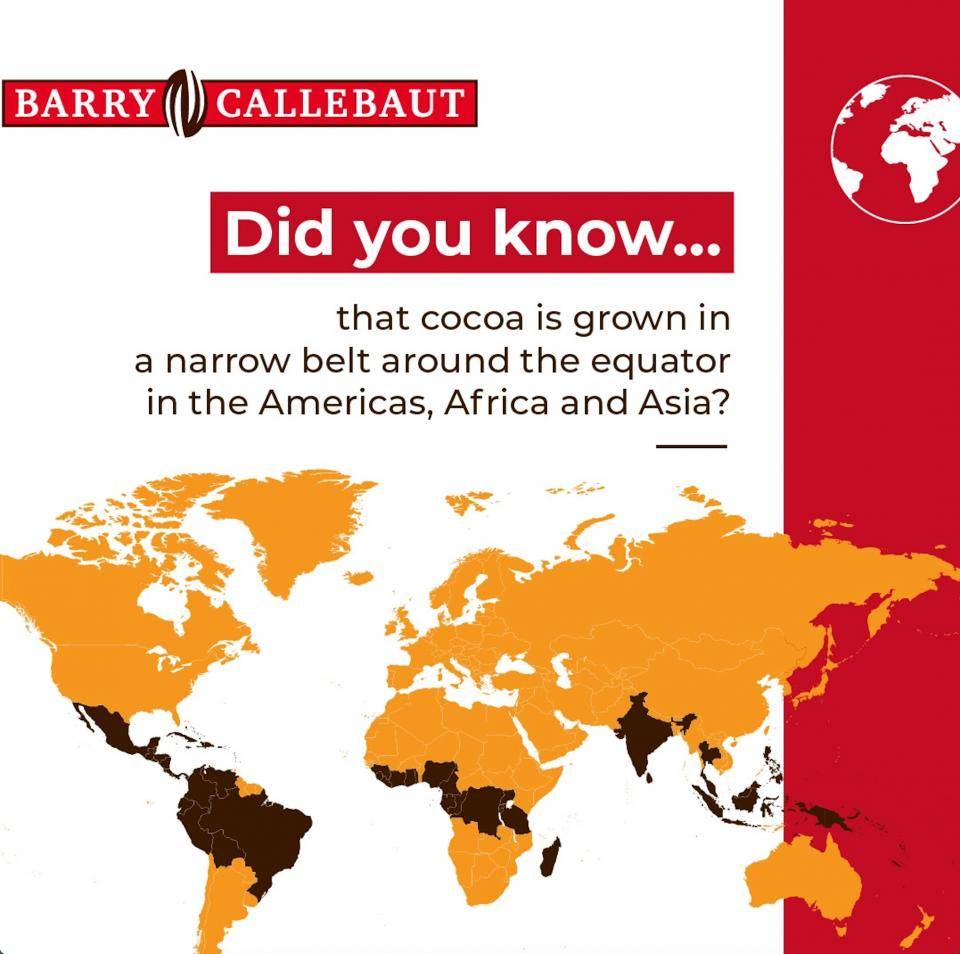

Cocoa is the essential ingredient for chocolate. It was brought to us by the Spanish explorers Columbus and Cortés who learned about it from their encounters in the “New World.” Initially they were baffled by the strange, almond-shaped cocoa beans. But they quickly discovered their value. The cocoa tree, which comes originally from the tropical rain forests of Honduras, Venezuela and Mexico, was soon cultivated in plantations set up by the Spanish. Nowadays, cocoa is grown in a narrow belt around the equator in the Americas, Africa and Asia.

The cocoa tree

The cocoa tree – Theobroma Cacao – only grows in the tropical heat of the equatorial forest. The shadow of the tall-growing plants protects the young tree against the burning sun or strong wind. After five years, it is strong enough to survive and start producing cocoa.

The cocoa tree flowers all year round, in two cycles of six months. Thousands of minuscule white (female) and pink (male) flowers adorn stem and branches. No more than forty of the thousands of flowers will eventually develop into cocoa pods.

After six months, the cocoa pods are full-grown and are ready to be harvested. There are two harvests per year. In Ivory Coast and Ghana, the main harvest lasts from October to March and the mid-crop from May to August.

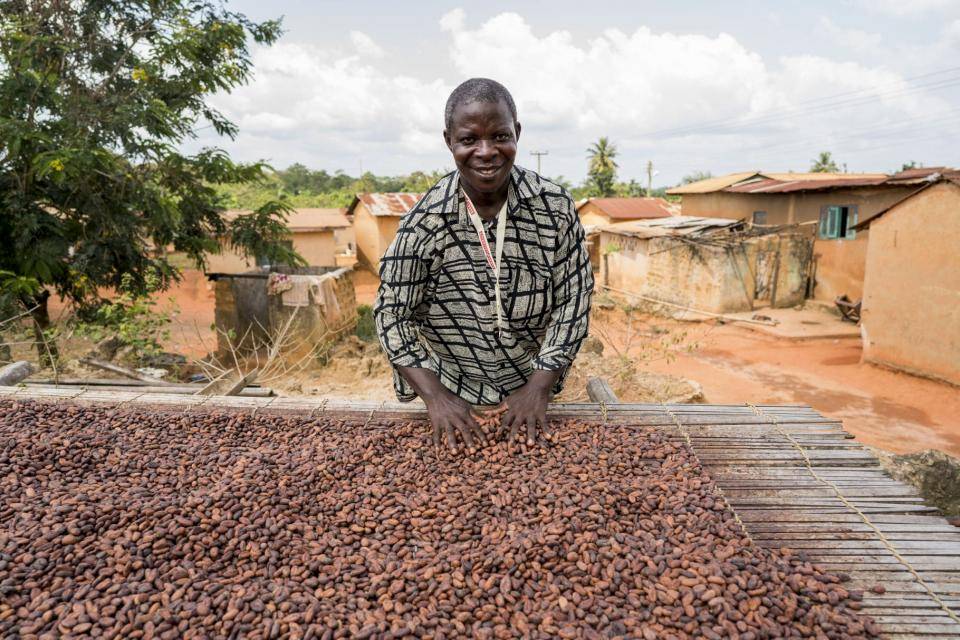

The farmers cut the outer peel of the cocoa pods open with long knives to collect the fruit pulp inside. This pulp contains 40 to 50 seeds, the cocoa beans. The beans are then left to ferment for five to seven days. This natural process removes any of the remaining fruit pulp around the beans. During fermentation, the beans change from gray to brown to purple and develop their aroma. After fermenting, the cocoa beans are spread out and left to dry in the sun for about six days.

When the beans are dry enough, the cocoa farmers bring their harvest to collection centers. Thousands of sacks of cocoa are taken from the collection centers to huge warehouses. The beans, packed in sacks or containers, are then shipped to the our cocoa processing and chocolate producing sites in Europe, America and Asia.

How is chocolate made?

Transforming cocoa beans into chocolate is a complex process, in which ingredients, time and temperature play a crucial role. By varying these three parameters, we are able to produce a variety of unique recipes

From cocoa bean to cocoa liquor

Jute sacks, filled with cocoa beans, arrive from Africa, Latin America and Asia. Cocoa beans from different origins are first examined for quality and then carefully mixed into a blend. This is done to obtain chocolate with a predetermined taste and aroma. Cocoa beans are cleansed of stones, dirt and sand and dried quickly under heaters. This makes it easier to break the beans and to remove the shell around them.

Cocoa nibs are then roasted, which develops their aroma. In special grinders, nibs are ground to a very fine, liquid mass, the cocoa liquor. This is one of the main ingredients of chocolate.

Cocoa liquor can be further processed into two different components: cocoa butter and cocoa powder. However, it can also be used directly as an ingredient in chocolate.

From cocoa liquor to chocolate

Depending on the kind of chocolate, different ingredients are used:

Dark chocolate: Cocoa liquor + cocoa butter + sugar

Milk chocolate: Cocoa liquor + cocoa butter + sugar + milk powder

White chocolate: Cocoa butter + sugar + milk powder

Vanilla or vanilla essence can be added to all types to enhance the taste.

The ingredients are first measured very precisely according to the recipe. These ingredients are mixed into a homogeneous chocolate dough. This mixture is then refined between rollers to form a fine chocolate powder in which the particles are so small that the human tongue can no longer distinguish them. This gives the finished chocolate an extremely smooth texture and a homogeneous flavor.

The chocolate powder is put into large tanks called conches. It is kneaded for several hours until the aromas have fully developed. Contact with air, heat and friction result in several different physical and chemical processes:

The cocoa butter present in the cocoa liquor melts. This also occurs with the milk fat from the milk powder used for milk and white chocolate.

- These fats are spread through all the minuscule particles in the chocolate mixture.

- Moisture present in the mixture evaporates.

- The volatile acids disappear partially or totally, depending on the conching time, and this affects the flavor of the chocolate.

- Moisture present in the mixture evaporates.

- The volatile acids disappear partially or totally, depending on the conching time, and this affects the flavor of the chocolate.

- A caramelization process also takes place, depending on the heat and the conching time. This also affects the flavor of the chocolate and is particularly important for milk and white chocolate.