Decade of delight: Recognizing 10 years of Barry Callebaut's chocolate manufacturing in Takasaki, Japan

Decade of delight: Recognizing 10 years of Barry Callebaut's chocolate manufacturing in Takasaki, Japan

Similarly, this November, we are proud to acknowledge not the 3rd, 5th or 7th, but the 10th year milestone of our operations in Takasaki. This anniversary is our testament to a decade of bringing chocolate and cocoa happiness into Japan.

Our chocolate manufacturing journey in Japan

We started our manufacturing journey in Japan in Amagasaki in 2008. After 5 years of operations, we relocated to Takasaki in 2013, where we have been operating for the past ten years.

By moving to Takasaki, we are able to be in closer proximity to our customers, which has enabled us to respond promptly to our customers’ needs and preferences. Throughout the past decade, we've also cultivated strong relationships with our customers in Japan and beyond. Our customer base has expanded to encompass a diverse range of clients, from small to medium-sized confectionery manufacturers to chocolatiers and artisan chefs.

Our customers’ trust in our commitment to quality, innovation, and sustainability has been instrumental in our journey and success. We want to keep elevating the chocolate experience for our customers and bring chocolate happiness to the entire nation

Our commitment to manufacturing excellence and high-quality assurance

Since the start of our journey, we have always maintained a commitment to manufacturing excellence. One example is our rigorous quality control measures to ensure that only the highest-quality, sustainable chocolate products make it to our customers.

In 2015, our factory successfully attained the FSSC 22000 certification, a food safety management system recognized by GFSI (The Global Food Safety Initiative). This certification comprehensively addresses food safety risks throughout our supply chain to support our quality control measures.

Besides adopting cutting-edge technology in our production site, we have also experienced substantial growth in our production capacity and effectively integrated new production lines. Presently, our factory boasts the capability to manufacture various chocolate products in various forms and volumes, all with a high level of efficiency.

Prioritizing customers and sustainability in business decisions

Our goal is to have every chocolate product that comes out of our production line exceeding our customers’ expectations for quality, flavor, and consistency. We pride ourselves in producing high quality and innovative ‘Made in Japan’ chocolate

Beyond high-quality products, our Takasaki plant can produce certified sustainable products, recognized and endorsed by Cocoa Horizons, a sustainability program initiated by Barry Callebaut to promote sustainable cocoa farming and improve the livelihoods of cocoa farmers. This initiative plays a pivotal role in responding to the growing consciousness and demands of our customers for sustainable products.

Fostering a vibrant Japanese Chocolate Industry through innovation

Japanese chocolate production, once reliant on imports, has surged into today’s vibrant domestic industry. A decade later, the country remains the top 3 largest market in the Asia Pacific Region for chocolate confectionery. According to Euromonitor, the retail sales of the Chocolate Confectionery market in Japan is valued at JPY 580 billion in 2023, a 6% increase from the previous year.

Among the many factors that have shaped the chocolate industry in Japan, innovation stands out as a significant catalyst that has ignited waves of enthusiasm in both the country and the wider region. In 2017, when Barry Callebaut introduced Ruby chocolate, the fourth type of chocolate, our Takasaki chocolate factory proudly became the first site in the Asia Pacific to successfully produce this groundbreaking chocolate variety.

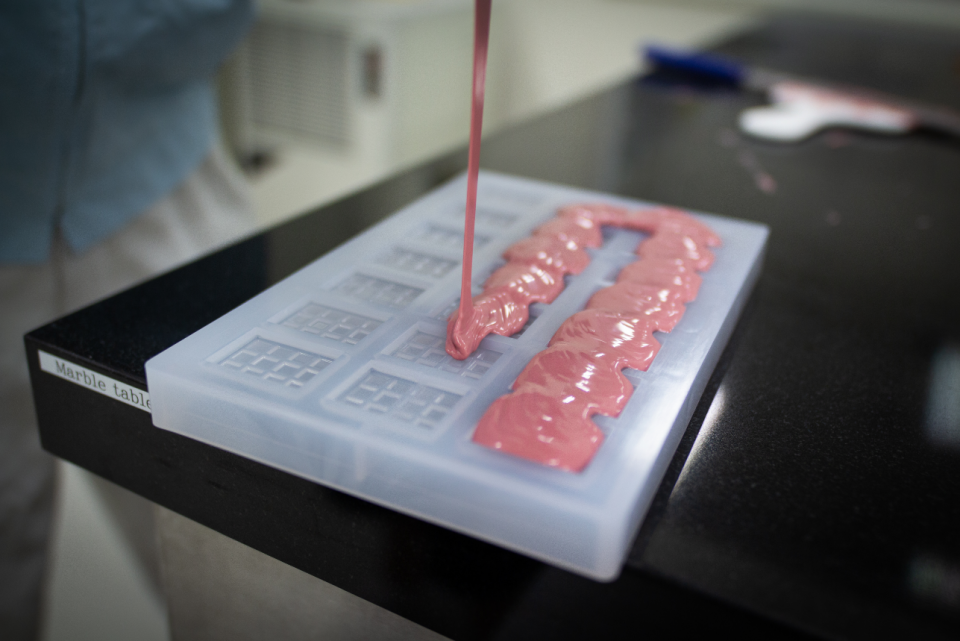

The Application Center in Takasaki also serves as a cornerstone of our commitment to innovation, where we conduct thorough testing of new developments prior to product launches. In these centers, we work closely with our customers for co-creation, training, and process optimization, leading the way in delivering chocolate experiences like no other.

It has been a fruitful decade filled with numerous achievements and memories. As we look into the future, we look forward to many more years of bringing chocolate and cocoa happiness to the region!

Find all media assets at this Flickr link